- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

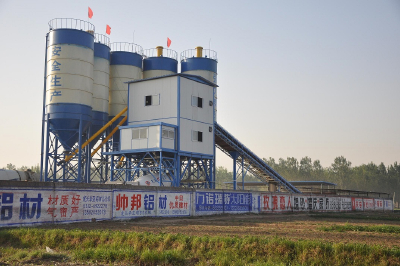

- Size: 32m*21m

- Place of Origin: Taian

- Brand Name: HONGJIAN

- Model Number: HZS120

- Weight: 51000.000 kg

Item | Specification | Qty. |

1 | Aggregate weighing system is composed of aggregate bin, frame, weighing hopper, aggregate conveyer and sensor. 1. Aggregate bin a. Volume: 15m3×4 b. Discharging gate: 8 c. Cylinder: diameter 80, journey 300 (with electromagnetic valve), 8 pieces d. Cylinder: diameter 100, journey 300 (with electromagnetic valve), four pieces 2. Weighing hopper: a. Volume: 1.8m3×4 b. Measure mode: measure alone c. Sensor: STL-1.5T, 1500kg×12 (Media America) d. Measuring precision: ±2% 3. Belt conveyer with cleaner a. Belt specification: 800mm b. Belt speed: 1.6 m/s 4. Electric drum 5.Vibrator: MVE200/3, power: 0.09kw, 6 sets | 1 |

2 | The elevating system adopts high flange belt conveyor. 1. Electric drum: width 1000 diameter 630 (with back stop), power:37kw 2. Angle: α=35° 3. Belt specification: B=1000 4. Belt speed: 2m/s 5. Convey capacity: 650t/h 6. Temporary storage hopper: 3m3 7. Discharging material gas cylinder: diameter 80, travel journey 200, Qty: 2 pieces | 1 |

3 | Mixing system Model: YJS2000 (Twin-horizontal forced type) Charging volume: 3000 L Discharging volume: 2000 L Motor: Y2-225S-4, power: 37kw×2 Mixing blade, lining board: wear resistance material System instruction: Planetary gear reducer, small volume, high efficiency, high reliability. Lining board and material of blade are chrome wear-resisting cast iron, reasonable design of angle and quality mixing efficiency, quick speed and long service life. Four axis ends are equipped with full automation sealing oil injection system. Discharging gate is controlled by hydraulic oil pump. | 1 |

4 | Mixing platform Discharge height: 3.8-4.0 m Mixing platform, tower Cover, out casing, electromagnetism valve, with mixed concrete temporary storage bin 2.0 m3, stairway, platform and handrails | 1 |

5 | Cement weighing system Cement weighing system is composed of cement weighing hopper, pneumatic butterfly valve, sensors and so on. Cement weighing hopper: 1. Volume: 1200L 2. Weighing range: 0~1200 kg 3. Weighing precision: ±1% 4. Sensor: SSB-Ⅲ-1000 (Media America) 5. Pneumatic butterfly valve: BV1F300S 6. Vibrator MVE40/15, power: 0.3kw | 1 |

6 | Fly ash weighing system is composed of fly ash weighing hopper, pneumatic butterfly valve, sensors and so on. 1.Fly ash weighing hopper a. Volume:800L b. Weighing range: 0~800 kg c. Weighing precision:±1% 2.Sensor: SSB-Ⅲ-500 Media America 3.Pneumatic butterfly valve: BV1F250S 4.vibrator Power: 0.03kw | |

7 | Water weighing system Water weighing system is composed of pool, water pump, water weighing hopper, pneumatic butterfly valve and so on. Supply water pump: GISG100-100-5.5KW Water injection pump: QY50-18-4 Pneumatic ball valve: DN32 Water scale volume: 550L Weighing range: 0~500 kg Sensor: 500kg×2 Discharging pneumatic butterfly valve: DN100 Weighing precision: ±1% | 1 |

8 | Additive weighing system including the box and pipeline Liquid additive weighing system is composed of additive storage box, additive weighing hopper, pneumatic butterfly valve, and sensors and so on. 1. Additive supplying pump, 2 sets; flux: 4m3/h (1.10L/s), power: 0.75kw 2. Pneumatic three way ball valve: DN25, 2 sets 3. Additive scale: 55L, 2 sets 4. Weighing range: 0~40 kg 5. Pipe pneumatic ball valve: DN25, 2 sets 6. Additive storage box: 3m3, 2 sets 7. Weighing precision: ±1% 8. Sensor: 100kg×2 9. Weighing hopper pneumatic butterfly: DN50, 2 sets | 1 |

9 | Pneumatic system is composed of air compressor, gas cylinder, electromagnetic and pneumatic components. 1. Air compressor: LB150350, 11KW 2. Gas storage box: 0.5 m3 (main tower and batcher each) 3. Electromagnetic: a. Main tower electromagnetic valve of pneumatic control case, 6 sets b. Cylinder electromagnetic valve, 14 sets c. Cement break electromagnetic valve: the quantity is the same as powder storage d. Air supply disposal components, two units (add one unit powder box) | 1 |

10 | Control system 1. The operation is integrated with management. It is easy and convenient to operate. 2. The batching system is controlled by the microcomputer. 3. The operating data of the mixing plant can be saved for more than ten years for the convenience of setting management. 4. The formula which can reach more then dozens can express by the figures for the convenience of distinguishing. 5. It has the function of error analysis and automatic checking. 6. Under the condition departing from the automatic control .The manual operating system can finish the control of the mixing plant such as batching, mixing discharging. 7. The heavy-current part of the system is separated from the weak-current part, so it enhances the ability of anti-jamming. Easy to maintain. 8.Can equip with sand and stone containing water rate measuring machine (need to book separately) 9. Equip with four pictures monitoring system: mixer, dosing machine, discharge hopper, Weighing system.

System instruction: The main hardware of this system all adopts Siemens Germany and advanced performance, high reliability and beautiful exterior. Console adopts man-machine engineering design, comfortable operation. | 1 |

11 | Screw conveyor 1. Cement screw conveyor a. specification: Ф273×11000 b. Qty:2 c. conveying capacity: 65t/h d. motor power: 15kw 2. Powder screw conveyer: a. specification: Ф219×11000 b. Qty: 2 c. conveying capacity: 45t/h d. motor power: 11kw

System instruction: a. Cement conveyer is fully sealed by a seal device, using soft joint. b. Using universal ball joint to regulate the angle, well seal. The clearance between screw blade and cylinder body is small, so it has high conveying efficiency. | 4 |

12 | Cement silo: 1.Specification: The piece-type 150t cement silo, 4 units 2.Cleaner: 4 units 3.Silometer: ULGA-240, 4 units

System instruction: Cement silo is equipped with upper and lower level indicator. Using a fan to blow the powder into the powder storage from its top. Mount a dust removal device on the top of the powder storage. Reducing the air pollution. The broken arch device is equipped on the top of the storage, which can be used manually or automatically. | 4 |

13 | Control room 1. Adopting colorful block board and heat insulation. 2. Air condition(changing in temperature)

System instruction: Control room is wide and bright. | 1 |

14 | The main tower is decorated with block board in a neat appearance. The dust collecting device is disposed on the top of the aggregate temporary hopper. | 1 |

15 | Contained dust collector, dust collecting pipe. 1. dust collector :FC3 2. dust collecting pipe | 4 |

- Size: 32m*21m

- Place of Origin: Taian

- Brand Name: HONGJIAN

- Model Number: HZS120

- Weight: 51000.000 kg

Item | Specification | Qty. |

1 | Aggregate weighing system is composed of aggregate bin, frame, weighing hopper, aggregate conveyer and sensor. 1. Aggregate bin a. Volume: 15m3×4 b. Discharging gate: 8 c. Cylinder: diameter 80, journey 300 (with electromagnetic valve), 8 pieces d. Cylinder: diameter 100, journey 300 (with electromagnetic valve), four pieces 2. Weighing hopper: a. Volume: 1.8m3×4 b. Measure mode: measure alone c. Sensor: STL-1.5T, 1500kg×12 (Media America) d. Measuring precision: ±2% 3. Belt conveyer with cleaner a. Belt specification: 800mm b. Belt speed: 1.6 m/s 4. Electric drum 5.Vibrator: MVE200/3, power: 0.09kw, 6 sets | 1 |

2 | The elevating system adopts high flange belt conveyor. 1. Electric drum: width 1000 diameter 630 (with back stop), power:37kw 2. Angle: α=35° 3. Belt specification: B=1000 4. Belt speed: 2m/s 5. Convey capacity: 650t/h 6. Temporary storage hopper: 3m3 7. Discharging material gas cylinder: diameter 80, travel journey 200, Qty: 2 pieces | 1 |

3 | Mixing system Model: YJS2000 (Twin-horizontal forced type) Charging volume: 3000 L Discharging volume: 2000 L Motor: Y2-225S-4, power: 37kw×2 Mixing blade, lining board: wear resistance material System instruction: Planetary gear reducer, small volume, high efficiency, high reliability. Lining board and material of blade are chrome wear-resisting cast iron, reasonable design of angle and quality mixing efficiency, quick speed and long service life. Four axis ends are equipped with full automation sealing oil injection system. Discharging gate is controlled by hydraulic oil pump. | 1 |

4 | Mixing platform Discharge height: 3.8-4.0 m Mixing platform, tower Cover, out casing, electromagnetism valve, with mixed concrete temporary storage bin 2.0 m3, stairway, platform and handrails | 1 |

5 | Cement weighing system Cement weighing system is composed of cement weighing hopper, pneumatic butterfly valve, sensors and so on. Cement weighing hopper: 1. Volume: 1200L 2. Weighing range: 0~1200 kg 3. Weighing precision: ±1% 4. Sensor: SSB-Ⅲ-1000 (Media America) 5. Pneumatic butterfly valve: BV1F300S 6. Vibrator MVE40/15, power: 0.3kw | 1 |

6 | Fly ash weighing system is composed of fly ash weighing hopper, pneumatic butterfly valve, sensors and so on. 1.Fly ash weighing hopper a. Volume:800L b. Weighing range: 0~800 kg c. Weighing precision:±1% 2.Sensor: SSB-Ⅲ-500 Media America 3.Pneumatic butterfly valve: BV1F250S 4.vibrator Power: 0.03kw | |

7 | Water weighing system Water weighing system is composed of pool, water pump, water weighing hopper, pneumatic butterfly valve and so on. Supply water pump: GISG100-100-5.5KW Water injection pump: QY50-18-4 Pneumatic ball valve: DN32 Water scale volume: 550L Weighing range: 0~500 kg Sensor: 500kg×2 Discharging pneumatic butterfly valve: DN100 Weighing precision: ±1% | 1 |

8 | Additive weighing system including the box and pipeline Liquid additive weighing system is composed of additive storage box, additive weighing hopper, pneumatic butterfly valve, and sensors and so on. 1. Additive supplying pump, 2 sets; flux: 4m3/h (1.10L/s), power: 0.75kw 2. Pneumatic three way ball valve: DN25, 2 sets 3. Additive scale: 55L, 2 sets 4. Weighing range: 0~40 kg 5. Pipe pneumatic ball valve: DN25, 2 sets 6. Additive storage box: 3m3, 2 sets 7. Weighing precision: ±1% 8. Sensor: 100kg×2 9. Weighing hopper pneumatic butterfly: DN50, 2 sets | 1 |

9 | Pneumatic system is composed of air compressor, gas cylinder, electromagnetic and pneumatic components. 1. Air compressor: LB150350, 11KW 2. Gas storage box: 0.5 m3 (main tower and batcher each) 3. Electromagnetic: a. Main tower electromagnetic valve of pneumatic control case, 6 sets b. Cylinder electromagnetic valve, 14 sets c. Cement break electromagnetic valve: the quantity is the same as powder storage d. Air supply disposal components, two units (add one unit powder box) | 1 |

10 | Control system 1. The operation is integrated with management. It is easy and convenient to operate. 2. The batching system is controlled by the microcomputer. 3. The operating data of the mixing plant can be saved for more than ten years for the convenience of setting management. 4. The formula which can reach more then dozens can express by the figures for the convenience of distinguishing. 5. It has the function of error analysis and automatic checking. 6. Under the condition departing from the automatic control .The manual operating system can finish the control of the mixing plant such as batching, mixing discharging. 7. The heavy-current part of the system is separated from the weak-current part, so it enhances the ability of anti-jamming. Easy to maintain. 8.Can equip with sand and stone containing water rate measuring machine (need to book separately) 9. Equip with four pictures monitoring system: mixer, dosing machine, discharge hopper, Weighing system.

System instruction: The main hardware of this system all adopts Siemens Germany and advanced performance, high reliability and beautiful exterior. Console adopts man-machine engineering design, comfortable operation. | 1 |

11 | Screw conveyor 1. Cement screw conveyor a. specification: Ф273×11000 b. Qty:2 c. conveying capacity: 65t/h d. motor power: 15kw 2. Powder screw conveyer: a. specification: Ф219×11000 b. Qty: 2 c. conveying capacity: 45t/h d. motor power: 11kw

System instruction: a. Cement conveyer is fully sealed by a seal device, using soft joint. b. Using universal ball joint to regulate the angle, well seal. The clearance between screw blade and cylinder body is small, so it has high conveying efficiency. | 4 |

12 | Cement silo: 1.Specification: The piece-type 150t cement silo, 4 units 2.Cleaner: 4 units 3.Silometer: ULGA-240, 4 units

System instruction: Cement silo is equipped with upper and lower level indicator. Using a fan to blow the powder into the powder storage from its top. Mount a dust removal device on the top of the powder storage. Reducing the air pollution. The broken arch device is equipped on the top of the storage, which can be used manually or automatically. | 4 |

13 | Control room 1. Adopting colorful block board and heat insulation. 2. Air condition(changing in temperature)

System instruction: Control room is wide and bright. | 1 |

14 | The main tower is decorated with block board in a neat appearance. The dust collecting device is disposed on the top of the aggregate temporary hopper. | 1 |

15 | Contained dust collector, dust collecting pipe. 1. dust collector :FC3 2. dust collecting pipe | 4 |