- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

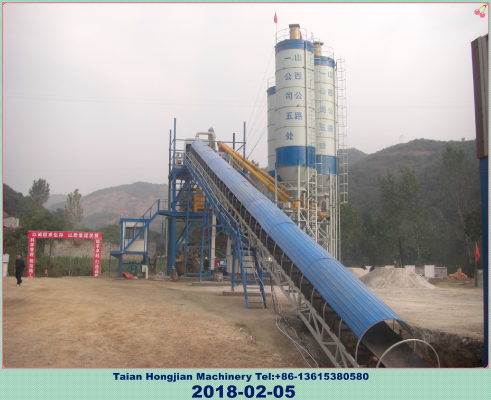

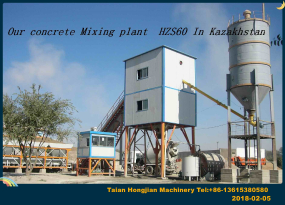

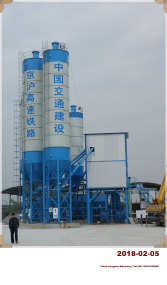

- Size: 23m*20m/40m*13m

- Place of Origin: TAIAN

- Brand Name: HONGJIAN

- Model Number: HZS60

- Weight: 43000.000 kg

Configuration of HZS60 Concrete Mixing Plant

Technical data:

Specification of Concrete Mixing Plant HZS60

Parts of HZS60 & Speciation | Photo | Qty. |

PLD1600(4) Aggregate hopper:4*7m3 Vibrator(sand Weighing hopper) Weighing hopper 2700L Belt conveyor: 1.25 m/s; Air cylinder Sensor 2000kg×2 Electromagnetism valve | 1 | |

Mixer JS1000A Twin shaft: JS1000 Input capacity: 1.6m3, output 1m3 Decelerator Motor: 37kw Internal Lining Manual oil pump device Hydraulic pressure cylinder Non-touch sensor |

inside of the mixer

mixing axes

| 1 |

Belt elevating machine Motor Power: 15kW Capacity160t/h Obliquity: α=35° Belt length: B=650 Speed of belt: 2 m/s Holding hopper: 2m3 Belt Support Platform Cover on top Decelerator Cleaner Weight tension Belt Cover Emergency pull cord safety switch | 1 | |

main structure Discharge height: 3.8 m Mixing platform Tower Cover, out casing Electromagnetism valve Dust catcher: VAM, Italy Filter area Stairway, platform, handrails | 1 | |

cement weighing Volume: 600L Weighing range: 0~600 kg Weighing precision: ±1% Cement weighing hopper: Pneumatic butterfly valve Sensor300 kg×3 Pneumatic butterfly valve: BV1F250S |

Sensor

| 1 |

powder weighing Capacity:400L Weighing range: 0~300 kg Weighing precision: ±1% Sensor: 200 kg×3 The pneumatic butterfly valve: BV1F250S | 1 | |

water weighing system The water supply pump model: QY40-16-3, motor power: 3 kW The water charging ball valve: DN32 The weighing scale capacity: 400L The sensors: 300kg×2 The weighing precision: ±1% The water discharging butterfly valve: DN125 | Water weighing sensor | 1 |

Chemical liquid additional weighing The mixing additive pump: GISG25-125, power:0.75 kW The three-way pneumatic ball valve Q615F-DN25 Addictive ball valve: DN25 Addictive scale capacity: 45L The addictive box capacity: 2m3 Weighing precision: ±1% Sensor : 100kg×1 Pneumatic butterfly valve: DN50 Chemical liquid additional box and pipeline | 1 | |

pneumatic system HZS60.10 The air compressor: W-1.5/7 11kW | cylinder | 1 |

controlling room in all Control room 1. Adopting colorful block board and heat insulation. 2. Air condition(changing in temperature)

System instruction: Control room is wide and bright. | 1 | |

electrical system in all In English and Chinese The control system is advanced with long life and allowed easy replacement. Only top quality electrical components are used in the control system. Automatic computer panel is designed to meet fully automatic and manual operation of plant by inputting and outputting weighing data of materials on the keyboard and mouse The computer of management and monitor carry out statistic production tables, daily report and monthly reports, test on line, troubles shooting and monitoring the plant. It stores all kinds of production data and saves 500 recipes and task numbers, which can be used and modified.

| 1 | |

1 | ||

Cement elevating system To elevate the cement from out side of cement silo to inside of silos. Model: D350 Productivity: 35 tons /hr One set can supply to two units of cement silos | 1 | |

Screw conveyor Used to transport the cement or the powder from silo to mixer. Cement screw conveyer 2 units Specification: Ф219×10000 Convey volume: 90t/h Motor power: 18.5kw | 2 | |

Cement silo: 50 tons Spare parts of Silos Quantity: 2 units Manual butterfly valve Deduster Level indicator Break arch device Two phase three links electromagnetism valve Safety valve Aeration Pads | 2 | |

The main tower is decorated with block board in a neat appearance. The dust collecting device is disposed on the top of the aggregate temporary hopper. |

- Size: 23m*20m/40m*13m

- Place of Origin: TAIAN

- Brand Name: HONGJIAN

- Model Number: HZS60

- Weight: 43000.000 kg

Configuration of HZS60 Concrete Mixing Plant

Technical data:

Specification of Concrete Mixing Plant HZS60

Parts of HZS60 & Speciation | Photo | Qty. |

PLD1600(4) Aggregate hopper:4*7m3 Vibrator(sand Weighing hopper) Weighing hopper 2700L Belt conveyor: 1.25 m/s; Air cylinder Sensor 2000kg×2 Electromagnetism valve | 1 | |

Mixer JS1000A Twin shaft: JS1000 Input capacity: 1.6m3, output 1m3 Decelerator Motor: 37kw Internal Lining Manual oil pump device Hydraulic pressure cylinder Non-touch sensor |

inside of the mixer

mixing axes

| 1 |

Belt elevating machine Motor Power: 15kW Capacity160t/h Obliquity: α=35° Belt length: B=650 Speed of belt: 2 m/s Holding hopper: 2m3 Belt Support Platform Cover on top Decelerator Cleaner Weight tension Belt Cover Emergency pull cord safety switch | 1 | |

main structure Discharge height: 3.8 m Mixing platform Tower Cover, out casing Electromagnetism valve Dust catcher: VAM, Italy Filter area Stairway, platform, handrails | 1 | |

cement weighing Volume: 600L Weighing range: 0~600 kg Weighing precision: ±1% Cement weighing hopper: Pneumatic butterfly valve Sensor300 kg×3 Pneumatic butterfly valve: BV1F250S |

Sensor

| 1 |

powder weighing Capacity:400L Weighing range: 0~300 kg Weighing precision: ±1% Sensor: 200 kg×3 The pneumatic butterfly valve: BV1F250S | 1 | |

water weighing system The water supply pump model: QY40-16-3, motor power: 3 kW The water charging ball valve: DN32 The weighing scale capacity: 400L The sensors: 300kg×2 The weighing precision: ±1% The water discharging butterfly valve: DN125 | Water weighing sensor | 1 |

Chemical liquid additional weighing The mixing additive pump: GISG25-125, power:0.75 kW The three-way pneumatic ball valve Q615F-DN25 Addictive ball valve: DN25 Addictive scale capacity: 45L The addictive box capacity: 2m3 Weighing precision: ±1% Sensor : 100kg×1 Pneumatic butterfly valve: DN50 Chemical liquid additional box and pipeline | 1 | |

pneumatic system HZS60.10 The air compressor: W-1.5/7 11kW | cylinder | 1 |

controlling room in all Control room 1. Adopting colorful block board and heat insulation. 2. Air condition(changing in temperature)

System instruction: Control room is wide and bright. | 1 | |

electrical system in all In English and Chinese The control system is advanced with long life and allowed easy replacement. Only top quality electrical components are used in the control system. Automatic computer panel is designed to meet fully automatic and manual operation of plant by inputting and outputting weighing data of materials on the keyboard and mouse The computer of management and monitor carry out statistic production tables, daily report and monthly reports, test on line, troubles shooting and monitoring the plant. It stores all kinds of production data and saves 500 recipes and task numbers, which can be used and modified.

| 1 | |

1 | ||

Cement elevating system To elevate the cement from out side of cement silo to inside of silos. Model: D350 Productivity: 35 tons /hr One set can supply to two units of cement silos | 1 | |

Screw conveyor Used to transport the cement or the powder from silo to mixer. Cement screw conveyer 2 units Specification: Ф219×10000 Convey volume: 90t/h Motor power: 18.5kw | 2 | |

Cement silo: 50 tons Spare parts of Silos Quantity: 2 units Manual butterfly valve Deduster Level indicator Break arch device Two phase three links electromagnetism valve Safety valve Aeration Pads | 2 | |

The main tower is decorated with block board in a neat appearance. The dust collecting device is disposed on the top of the aggregate temporary hopper. |